Table of Contents

Toggle6 Advantages of Steel Rule Cutting Die

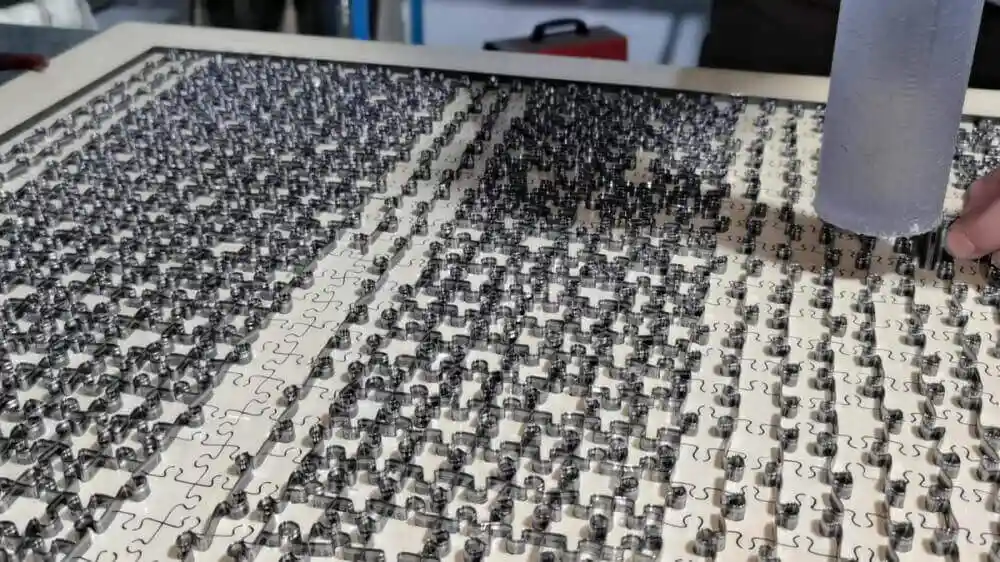

We are Lexson Cutting, a leading manufacturer of steel rule cutting die in China. Our orders are exported to more than 30 countries worldwide. In the following, I will introduce six major advantages of steel rule cutting dies.

Cost-effectiveness

Steel rule die are relatively inexpensive to produce and have a long lifespan, making them the preferred choice for mass production due to this cost-effectiveness.The production cost of it is relatively low and they can be mass-produced. Due to their high efficiency and accuracy, they can reduce labor and material waste, and improve production efficiency and quality. In addition, the fast production speed of it allows for quick fulfillment of customer production needs, reducing production costs.Therefore, products made using steel rule cutting dies typically have lower costs compared to other manufacturing methods.

High precision

Steel rule die is a highly precise mold processing technique that can manufacture high-precision cutting dies, resulting in higher product quality and accuracy. The production and maintenance of it for die-cutting are highly strict, resulting in smooth edges on the cut products without burrs or cracks. This is particularly crucial in the manufacturing of high-demand products such as precision packaging and automotive interiors. The high-precision cutting of steel rule dies guarantees product quality and appearance, increases customer satisfaction, and ultimately enhances market competitiveness. By using high-precision dies, the dimensions, shapes, and appearance of the products can be ensured to meet customer requirements.

Highly customizable

Steel rule cutting die made for cutting and shaping molds are suitable for a wide range of materials. As a result, these dies are applicable in various industries and fields of application. The products made by Steel Rule Cutting Die have a high degree of customization and can be made in various shapes and sizes according to customer requirements, which is very popular in the production of customized products. This diversity makes it a versatile solution widely used in different industries.

High Reliability

Steel rule cutting die are very sturdy and durable, and can maintain high precision and efficiency over long periods of time. The molds have a long lifespan and can handle a large volume of die-cutting tasks. It can not only create simple shapes but also various complex shapes, which is very popular in many industries such as printing, packaging, automotive, electronics, and toy industries. This durability reduces the frequency of mold maintenance and replacement, thereby lowering production costs.

wide applicability

Steel rule cutting die can be used for cutting most types of materials and products, including paper, plastic, metal, wood, rubber, leather and more, which makes it widely applicable in various industries. They are not only suitable for industries such as packaging, printing, and automotive, but also for industries such as footwear, luggage, electronics, and others. The broad applicability of steel rule dies makes them a highly practical tool.

Time-saving

The use of steel rule cutting dies can save manufacturers time. The production cycle for a steel rule die is typically short, especially for simple shapes which can be completed within a few hours. For complex shapes, it usually takes several days for production, which can be used on high-speed die-cutting machines, allowing for quick and accurate cutting of products, which can be used for production of any scale, from small-scale to large-scale, and can be completed quickly and efficiently. The production efficiency of it is very high, especially in large-scale production. Due to its high efficiency, it can help businesses quickly complete production tasks and meet customer demand, which can cut out the desired shape all at once, manufacturers do not have to make multiple cuts or cut by hand, thus saving time and effort. Additionally, products made with it are typically more precise than other machining methods and better able to meet customers’ high-quality requirements.

Steel rule cutting die conclusion

If you are looking for a cutting method that features high precision, low cost, high productivity, versatility, time-saving, and safe and reliable operation, which is an excellent choice. Lexson Cutting has been specializing in the production of die making for over 20 years.

In our previous article, we presented the complete 1000 piece puzzle die production process. Interested readers can refer to it for more information

You can also see how Lexson Machinery’s hydraulic press works in conjunction with Lexson Cutting’s dies through the following video.